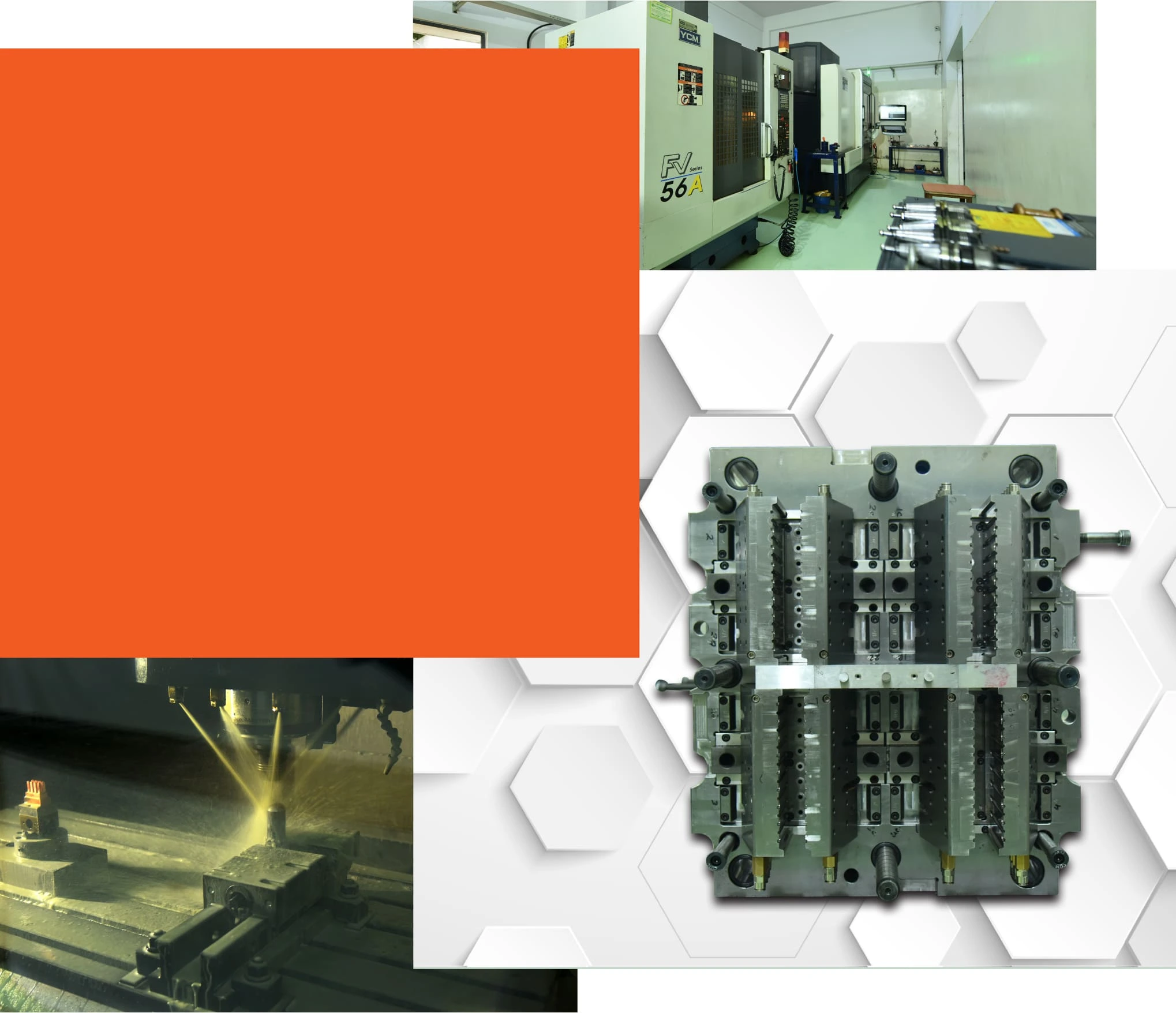

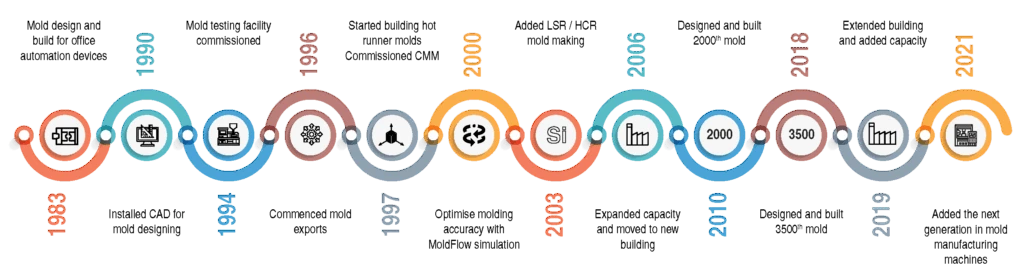

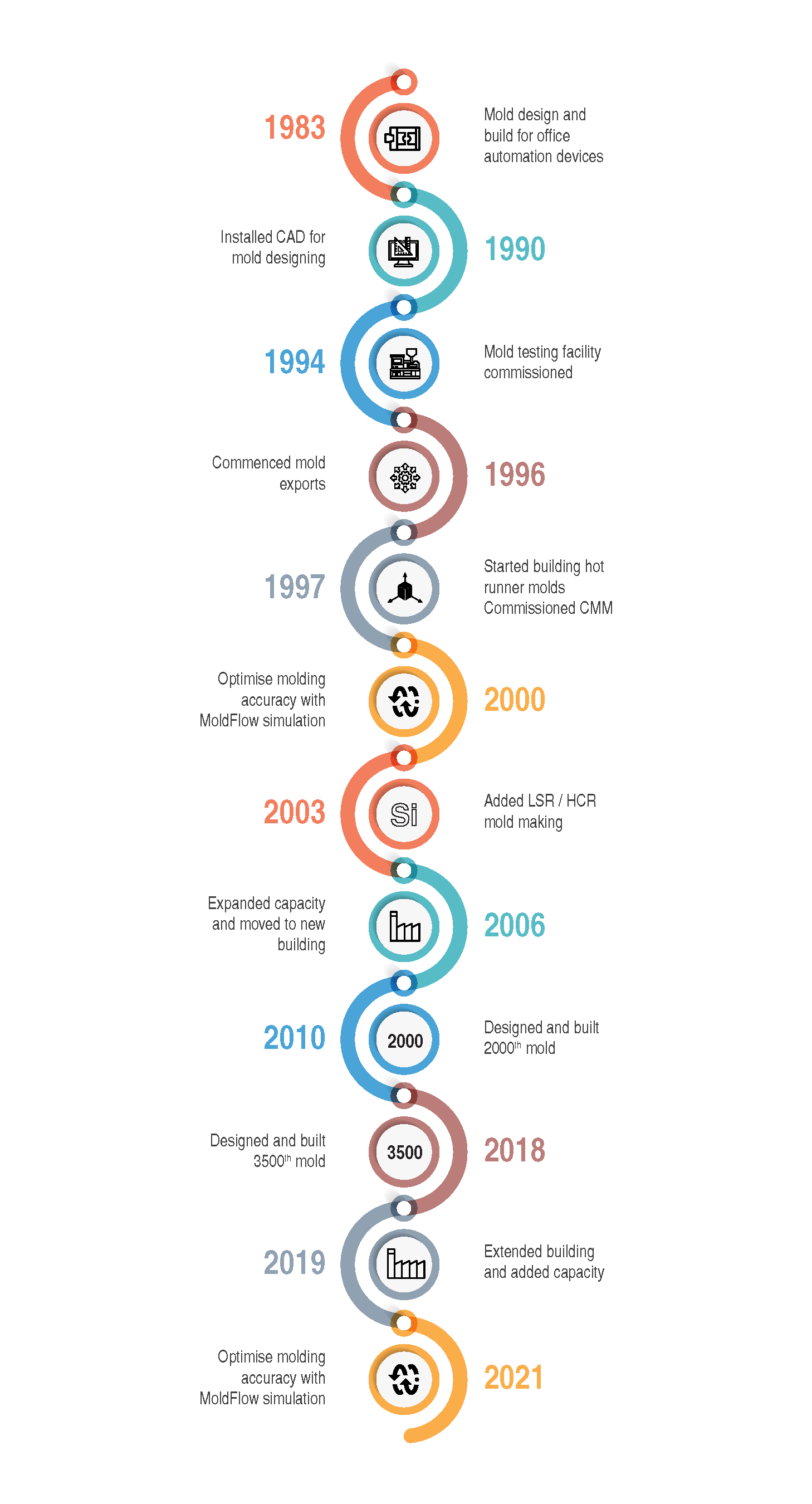

Leading Precision Mold Maker Since 1983

Laxmi commenced its mold manufacturing enterprise in 1983. The company deploys the latest technology to manufacture high-precision multi-cavity hot runner injection molds.

Our investments in top-of-the-line digitally driven manufacturing systems and quality management systems allows for continuous process improvements.

The profitability of the production process depends largely on the quality, performance and

reliability of the mold. We export our molds to USA, UK, Germany, Holland, Sweden and France. The molds we manufacture are for diverse

segments, spanning industries like: medical,

aerospace, writing instruments, electrical and

electronics.